- PROJECT CODE: N1-0223

- PROJECT TITLE: Reverse supply chain of residual wood biomass

- PROJECT TEAM: Jakub Sandak, PhD (leader), Miklós Krész, David Balazs, Aleksander Tošić

- PERIOD: 01.12.2021 – 30.11.2024

- BUDGET: €389,880.00 (€135,000.00 for InnoRenew CoE)

- FINANCING: Slovenian Research Agency (ARRS)

- COORDINATOR: Sieć Badawcza Łukasiewicz, Institute of Logistics and Warehousing (Poland)

- PARTNERS: InnoRenew CoE (Slovenia); Vienna University of Technology (Austria)

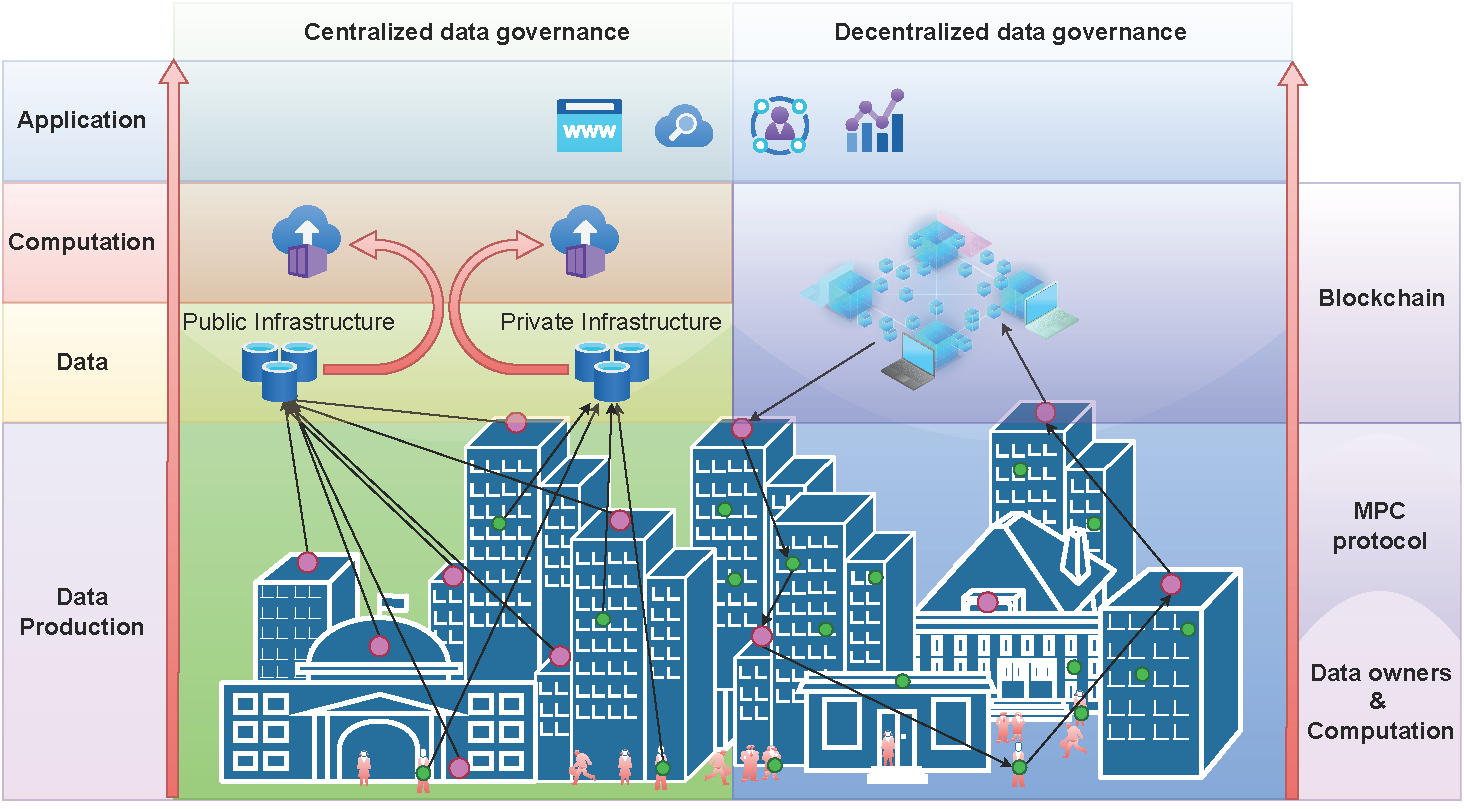

Optimization problems in the reverse logistics network of residual wood biomass will be modeled as the output of the project, and efficient solution methods will be implemented. As these models and methods will consider the multi-objective nature of these relevant optimization questions, they will have both an environmental and economic impact. Companies will be able to utilize them to decrease their environmental footprint (e.g., reduce the amount of resources sent for landfill or incineration, decrease the number of trucks used and distance traveled) as well as streamline their economic efficiency (e.g., optimize transportation routes, save inventory or truck space with efficient packing schemes). The developed methods will be tested in a simulation framework, which also has the potential to be expanded into a decision support system in the future. This will allow the simulation of various scenarios with different parameter set-ups and provide multiple good-quality suggestions to end-users for a given problem instance.

Real-world and simulated information connected to the availability of residual wood biomass will also be collected through empirical studies. The study of this data will reveal unique characteristics and patterns that can be generalized for other biomass supply chains, making it easier to produce randomized realistic test instances for future research.

InnoRenew CoE project activities

InnoRenew CoE researchers will contribute to the analysis of the reverse wood value chain and identification of its most important optimization problems. They will also assist in development of mathematical models and exact algorithms for their solutions as well as implement a simulation environment where large-scale testing of both exact and approximate algorithms will be possible.