July 26, 2024

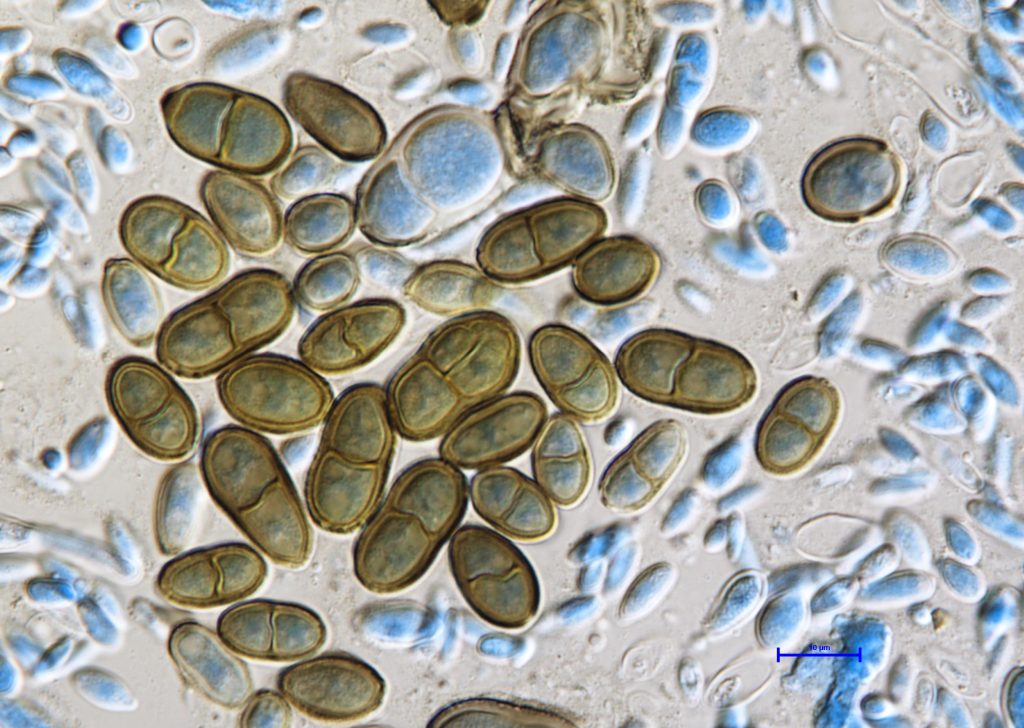

The InnoRenew CoE research laboratories also include an Engineered Living Materials Laboratory that implements biomimetic principles for the development of new materials and modification processes. This laboratory is the newest one and was created in the frame of the ERC project ARCHI-SKIN (#101044468) funded by the European Union. In the ELM lab, we design, fabricate, and characterize “smart”, active, or multifunctional materials composed either entirely, or partly, of living cells. Various microorganisms (bacteria, fungi) might be incorporated as living and bioactive components in the form of a matrix or be a part of the living scaffold.

The ELM laboratory is equipped with two growth chambers where temperature, light and humidity can be controlled. An automated colony counter allows high throughput analysis of plates with microbial colonies including differentiation by color, size, and shape. The mixer mill enables dry and wet grinding in small volumes, and it is used for cell disruption in the process of nucleic acid or protein extraction. The microplate reader can be used for absorbance, fluorescence and luminescence measurements that are employed in various assays. A portable microbial air sampler is used to detect airborne micro-organisms and allow indoor and outdoor sampling. The stirred-jacketed photobioreactor is suitable for the growth of various microorganisms (including phototrophic organisms). It has a fully removable light module, which allows its use as a traditional fermenter/bioreactor. The research is conducted in sterile conditions, inoculation is performed in a microbiological safety chamber and equipment is cleaned in steam sterilizer. Microbial cultures are stored in an ultra-low temperature freezer allowing reliable, and efficient protection of temperature-sensitive samples.

The ongoing research is related to the development of a multifunctional coating system that relies on a biologically inspired concept for protecting materials, as an unconventional alternative to traditional coatings. The concept is based on a technically applicable, controlled, and optimized biofilm formation that effectively protects the substrate surfaces, assuring optimal service life performance and different functionalities including self-healing. The developed coating formulations are optimized for three types of substrates: bio-based porous (e.g., wood, wood-based composites), inorganic porous (e.g., concrete, stone, bricks), and non-porous (plastic and steel) and are designed to work effectively in various climatic conditions. The living coatings developed in the ELM lab are entirely biobased and free from biocides and fossil-based ingredients. Their development boosts innovation for safe and sustainable chemicals according to the EU’s 2050 long-term strategy for a climate-neutral Europe. Application of the developed coating in big cities could potentially contribute to lowering air pollution due to the bioremediation capacity of fungi selected as a candidate for engineered biofilm. The enhancement in performance due to the self-repair functionality will improve the environmental impact and reduce the cost burden of premature failure in service and maintenance activity.

The activity of the ELM lab can support industrial partners in out-of-the-box material design where unconventional methodology is required. The pioneering approach for protecting materials aims to push the boundaries of traditional materials concepts toward the development of materials capable of interacting, adapting, and responding to environmental changes. By adding living microbial cells to bulk or surface we aim to outperform the drawbacks of conventional building materials and assure that novel functionalities are long-lasting.

List of equipment in the ELM laboratory

Dr. Anna Sandak, dr. Karen Butina Ogorelec, Faksawat Poohphajai and Ana Gubenšek, InnoRenew CoE